Air Handler vs. Furnace: What’s the Difference?

When you’re dealing with HVAC equipment, understanding the difference between an air handler and a furnace can save you time, money, and confusion. Both components play crucial roles in your home’s heating and cooling system, but they serve different purposes and work in distinct ways.

Many homeowners struggle to distinguish between these two essential pieces of equipment. This confusion often leads to miscommunication with contractors, incorrect maintenance decisions, and sometimes even purchasing the wrong replacement parts. Whether you’re planning a system upgrade, troubleshooting issues, or simply want to become more knowledgeable about your home’s HVAC system, understanding these differences is essential.

This comprehensive guide will explore:

- What an air handler is and how it functions

- The role of a furnace in your HVAC system

- Key differences between air handlers and furnaces

- Maintenance considerations for each system

- Cost factors that influence your decision

🤔 What Is an Air Handler?

An air handler is a crucial component of your HVAC system that circulates conditioned air throughout your home. Unlike a furnace, which generates heat through combustion, an air handler works as part of a heat pump or air conditioning system to move air that has been heated or cooled by an external unit.

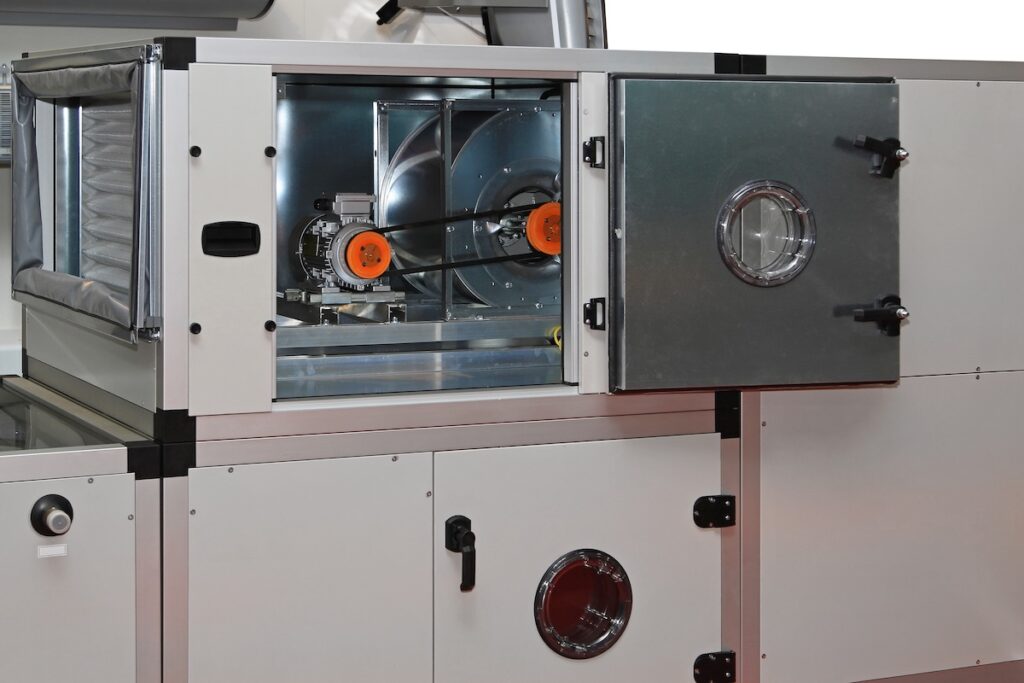

The primary function of an air handler involves several key processes. It houses the blower fan that pushes air through your ductwork, contains the evaporator coil that removes heat and humidity from the air during cooling mode, and includes air filtration systems that clean the air before it circulates through your home. Many modern air handlers also feature variable-speed motors that adjust airflow based on your home’s specific needs.

Components of an Air Handler

- The blower assembly, including the motor and fan, moves air through the system to ensure efficient circulation.

- The evaporator coil contains refrigerant that absorbs heat from indoor air during cooling.

- Air filters trap dust, pollen, and airborne particles to prevent them from circulating in your home.

- Additional features may include electric heating elements, airflow dampers, and advanced controls for smart thermostats or variable refrigerant flow for precise temperature control.

🔎 Understanding Furnaces

A furnace generates heat through combustion or electrical resistance, then distributes that heated air throughout your home via ductwork. Unlike air handlers that rely on external units for heating and cooling, furnaces are self-contained heating systems that create warmth internally.

Most residential furnaces operate on natural gas, propane, oil, or electricity. Gas furnaces burn fuel in a combustion chamber, transferring heat to air that passes over a heat exchanger. Electric furnaces use heating elements similar to those in electric ovens to warm the air directly.

The heated air is then pushed through your home’s ductwork by an internal blower fan. Modern furnaces achieve high efficiency ratings through advanced heat exchanger designs, variable-speed blowers, and sophisticated control systems that optimize fuel consumption.

Types of Furnaces

- Gas Furnaces: The most common option in areas with natural gas service, offering cost-effective heating and efficiency ratings above 95% in high-efficiency models. Exhaust gases are vented through a chimney or direct vent system.

- Electric Furnaces: A combustion-free option, ideal for homes without gas service or where electricity costs are competitive.

- Oil Furnaces: Less common but still used in regions with readily available and affordable heating oil.

- Heat Pumps: A hybrid system that uses electricity to move heat, providing both heating and cooling. Popular in moderate climates.

⚖️ 7 Key Differences Between Air Handlers and Furnaces

Understanding the fundamental differences between air handlers and furnaces helps you make better decisions about your HVAC system. Here are the most important distinctions:

1. Heat Generation Method

Furnaces create heat internally through combustion or electrical resistance. They burn fuel or use electric elements to generate warmth that transfers to the air circulating through the system. Air handlers, conversely, do not generate heat themselves but circulate air that has been conditioned by external equipment like heat pumps or air conditioning units.

2. System Configuration

A furnace operates as a standalone heating unit that can function independently to heat your home. Air handlers require connection to external equipment to provide heating or cooling. This means air handlers are part of a larger system, while furnaces can serve as the primary heating source without additional outdoor equipment.

3. Fuel Requirements

Furnaces typically require a fuel source such as natural gas, propane, heating oil, or significant electrical power for resistance heating. Air handlers primarily use electricity to power fans and control systems, with the actual heating and cooling provided by connected heat pumps or air conditioning units.

4. Installation Location

Both systems can be installed indoors, but their installation requirements differ significantly. Furnaces need access to fuel lines (for gas or oil units) and proper venting for combustion byproducts. Air handlers require refrigerant line connections to outdoor units but don’t need fuel lines or combustion venting.

5. Seasonal Operation

Furnaces primarily operate during heating season, though they may run minimally during summer months to circulate air if connected to a separate air conditioning system. Air handlers operate year-round, providing both heating and cooling distribution depending on the season and system configuration.

6. Efficiency Ratings

Furnace efficiency is measured using Annual Fuel Utilization Efficiency (AFUE) ratings, which indicate how much fuel converts to usable heat. Air handler efficiency relates to electrical consumption for air movement and is often measured by the efficiency of the connected outdoor equipment rather than the air handler itself.

7. Maintenance Requirements

Furnace maintenance focuses on combustion components, heat exchangers, and fuel delivery systems. Air handler maintenance emphasizes air filtration, blower components, and refrigerant coils. Both require regular filter changes, but furnaces need additional attention to combustion safety and exhaust systems.

🛠️ Maintenance and Longevity

Proper maintenance ensures your equipment stays in top condition, preventing costly repairs or replacements. Focusing on longevity maximizes your investment and keeps everything running efficiently over time

Maintenance for Air Handlers

Proper maintenance is essential for air handlers to ensure longevity. Key tasks include:

- Regular filter changes

- Coil cleaning

- Blower motor maintenance

Additionally, the connected outdoor equipment requires seasonal maintenance such as refrigerant level checks and condenser coil cleaning.

Maintenance for Furnaces

Furnace maintenance focuses on safety and efficiency. Important steps include:

- Inspecting heat exchangers for cracks or corrosion

- Cleaning burner assemblies

- Checking gas connections for leaks

- Ensuring proper venting operation

Annual professional inspections help identify and address potential safety issues early.

Lifespan of Air Handlers and Furnaces

With proper maintenance, both systems generally last 15-20 years. However:

- Air handlers may have longer lifespans as they avoid the stresses of combustion processes.

- Outdoor equipment connected to air handlers may require earlier replacement or repairs.

- Furnace components may need replacement sooner due to wear and tear.

💵 Cost Considerations Between Air Handlers and Furnaces

Understanding the cost differences between air handlers and furnaces is crucial when planning your HVAC system. These costs can impact both your upfront investment and long-term energy efficiency.

Initial Equipment Costs

Initial costs vary between air handlers and furnaces. High-efficiency furnaces tend to cost more upfront than basic air handlers. However, air handler systems require outdoor equipment, which increases the total system cost. When comparing costs, consider the entire system rather than individual components.

Operating Costs

Operating costs depend on local fuel and electricity prices, system efficiency, and usage patterns. Gas furnaces generally have lower operating costs in areas with inexpensive natural gas. Air handler systems with heat pumps can be cost-effective for heating and cooling in moderate climates but might need backup heating in extremely cold conditions.

Long-Term Costs

Long-term costs include maintenance, repairs, and eventual replacement. Furnaces may have higher maintenance costs due to their complex combustion systems, while air handler systems divide maintenance needs between the indoor and outdoor equipment.

🏠 Making the Right Choice for Your Home

Choosing the right air handler is essential for maintaining a comfortable and energy-efficient home. With so many factors to consider, from system compatibility to energy performance, it’s important to have a team you can trust to guide you through the process. That’s where we come in. Our experienced professionals specialize in AC installation and are committed to ensuring your air handler is perfectly suited to your home’s unique needs.

From initial consultation to seamless installation, we provide honest recommendations, expert insights, and reliable service every step of the way. Ready to upgrade your home’s comfort? Contact us today to schedule your consultation and let us help you find the perfect air handler for your space. Your comfort is our priority!

Ultimate Comfort Awaits